摘要

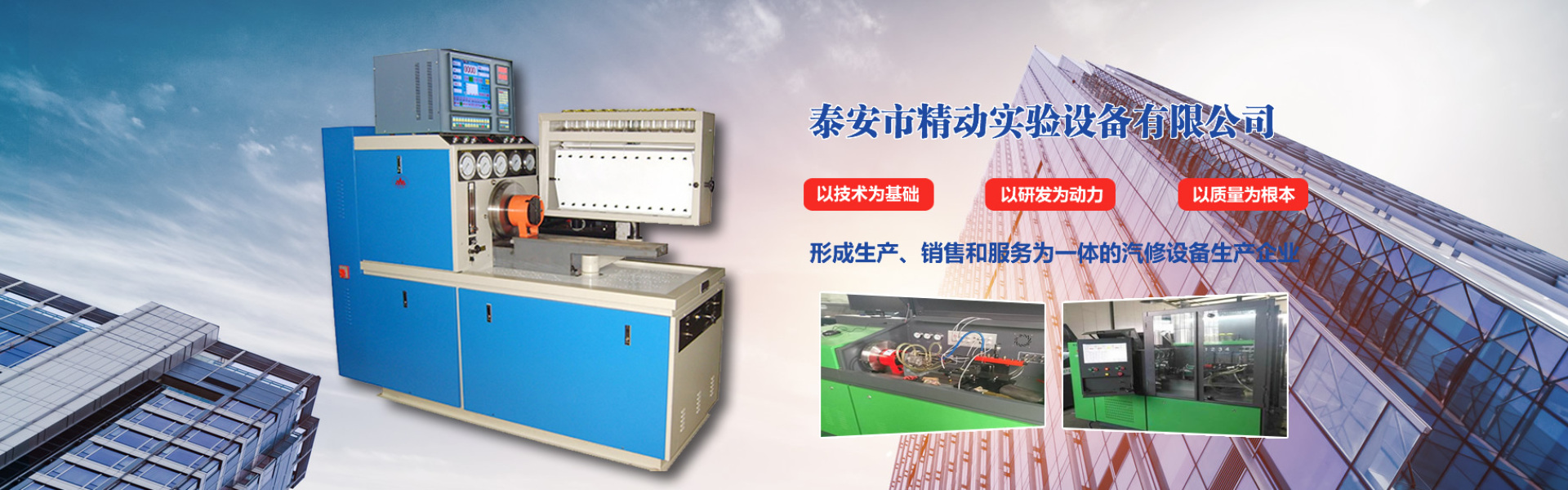

下面的内容是对于喷油泵试验台的适用场合的事项阐述,所展示的喷油泵试验台图片都是现场拍摄,提供的内容都是经过泰安精动实验设备有限公司高压共轨试验台厂家经验所得,请点击进入查看更多机油泵试验台的相关行业信息吧。

喷油泵试验台产品介绍

喷油泵试验台的适用场合:

油泵试验台作为常见的一种调试试验设备,在喷油泵的生产与维修中发挥着关键的作用。依据占有市场份额较大的机械式喷油系统,厂家特别研发了12psb喷油泵试验台,该试验台适用于中国市场上所有直列式和分配式机械喷油泵。

喷油泵试验台特点:

1、转速有十个档位,可以随时调节。

2、转速、记数、温度数字显示,记录方便

3、自动化程度高,燃油温度可以进行自动控制

4、具有正负两个系统,同时正负压系统配有气源

5、自带12V/24V直流电源

6、保护功能齐全,具有过压、过载、过热保护功能

喷油泵试验台车间要求及安装:

1、有的试验台是带有燃油冷却系统的,应将自来水管与燃油冷却器连接,以便冷却油温。

2、12psb喷油泵试验台应该安装在不受潮湿的环境下,不能靠近腐蚀气体

3、喷油泵试验台应安装在稳固的水平面上。要用水平仪找好水平位置进行安装。

4、喷油泵试验台电机电源是三相四线电源,设备的机壳应良好接地。

5、试车启动电动机前的检查工作相当重要,仔细检查各连接部分是否紧固可靠,万向节螺钉坚固牢靠,要罩好防护罩。试验台在高速空转时,要及时拆掉应万向节,以防发生不必要的事故。

6、起动时,应特别注意供油泵的旋转方向和泵旋向标牌所示的旋向一致。当供油泵的旋向反向时,应调整电源相位使其旋向正确。

7、喷油泵试验台试运转前,在试验台上防锈油要仔细清除,并在需要注油的地方注入规定的油料。

喷油泵试验台发展趋势:

(1)喷油泵试验台生产厂家生产的设备都是批量化的,因此,对于试验台的自动化程度要求也越来越高,如喷油泵快速装夹具及喷油量快速数字化测量等;而维修行业则要求试验台应能适应多种喷油泵的调试,具备较齐全的附件。

(2)利用计算机测控技术在喷油泵试验台的技术上将会成为一种趋势,使喷油泵调试中的各项条件和技术参数的测量完全以数字化方式进行自动测量,成为喷油泵产品技术及质量不断提高的条件

关于喷油泵试验台的相关内容就先介绍到这里,泰安精动试验设备厂是一家集高压共轨试验台生产,喷油泵试验台销售为一体的公司,多年来,致力于研究开发新型试验设备,已取得突破性进展,试验台价格优惠,值得广大客户信赖。如想了解更多相关设备的介绍,可进入网站了解。

Applicable occasions of fuel injection pump test bench:

As a common debugging and testing equipment, fuel injection pump test-bed plays a key role in the production and maintenance of fuel injection pump. According to the mechanical fuel injection system with a large market share, the manufacturer of the fuel injection pump test bench has specially developed a 12psb fuel injection pump test bench, which is applicable to all in-line and distributed mechanical fuel injection pumps in the Chinese market.

Characteristics of fuel injection pump test bench:

1. The speed has ten gears, which can be adjusted at any time.

2. Speed, counting and temperature digital display, convenient for recording

3. The degree of automation is high, and the fuel temperature can be automatically controlled

4. It has positive and negative systems, and the positive and negative pressure system is equipped with air source

5. With 12v/24v DC power supply

6. The protection function is complete, with overvoltage, overload and overheating protection functions

Workshop requirements and installation of fuel injection pump test bench:

1. Some test benches are equipped with fuel oil cooling system, and the water pipe should be connected with the fuel oil cooler to cool the oil temperature.

2. 12psb fuel injection pump test bench should be installed in an environment free from moisture and should not be close to corrosive gases

3. The fuel injection pump test bench shall be installed on a stable horizontal plane. Use a level to find the horizontal position for installation.

4. The motor power supply of the fuel injection pump test bench is a three-phase four wire power supply, and the shell of the equipment should be well grounded.

5. The inspection work before commissioning and starting the motor is very important. Carefully check whether the connecting parts are fastened and reliable, the universal joint screws are firm, and the protective cover should be covered. When the test bench idles at high speed, the universal joint should be removed in time to prevent unnecessary accidents.

6. When starting, pay special attention to the rotation direction of the oil supply pump and the rotation direction shown on the pump rotation direction label. When the rotation direction of the oil supply pump is reversed, adjust the power phase to make it rotate correctly.

7. Before the test run of the fuel injection pump test bench, the antirust oil on the test bench shall be carefully removed, and the specified oil shall be injected into the place where oil injection is required.

Development trend of fuel injection pump test bench:

(1) The equipment produced by fuel injection pump test-bed manufacturers are all in batches, so the requirements for the automation of the test-bed are also higher and higher, such as rapid fixture installation of fuel injection pump and rapid digital measurement of fuel injection quantity; The maintenance industry requires that the test bench should be able to adapt to the commissioning of a variety of fuel injection pumps, with relatively complete accessories.

(2) The use of computer measurement and control technology in the fuel injection pump test-bed technology will become a trend, so that the conditions and technical parameters in the fuel injection pump commissioning are measured automatically in a digital way, which becomes the condition for the continuous improvement of the fuel injection pump product technology and quality

The relevant content of the fuel injection pump test-bed will be introduced here first. Tai'an Jingdong test equipment factory is a company integrating the production of high-pressure common rail test-bed and the sales of fuel injection pump test-bed. Over the years, it has been committed to the research and development of new test-bed equipment, and has made breakthrough progress. The price of the test-bed is preferential, which is worthy of the trust of our customers. If you want to know more about the relevant equipment, you can go to the website.

英文由百度翻译,仅供参考。